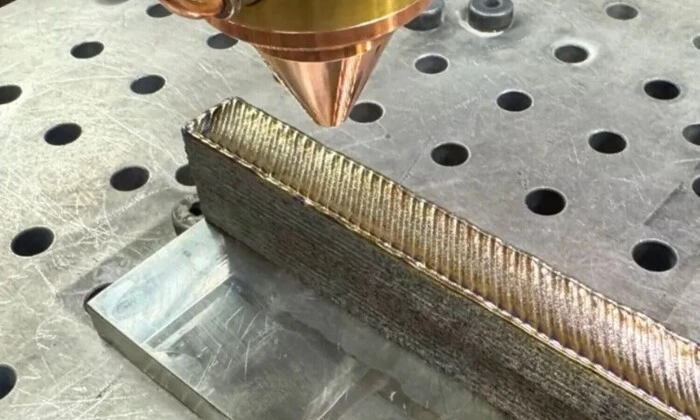

Scientists have created a cheaper and stronger titanium for 3D printing: what this will change

Engineers from the Royal Melbourne Institute of Technology (RMIT) have introduced a new titanium alloy for 3D printing that not only has significantly improved strength characteristics compared to traditional materials, but is also produced at a lower cost. The engineers' work has led to the creation of a material without the expensive element vanadium, making it more affordable to manufacture.

We were able to create a titanium alloy with a uniform structure while also reducing costs, making the material stronger and more ductile

- explained Ryan Brook, the lead author of the research.

The new alloy costs a third less to manufacture than standard titanium alloys, opening up new opportunities for its use in aviation, space technology, and medicine. The university has already applied for a patent and is looking for partners to quickly implement the innovation into industrial production.

The alloy developed by the team is 29% cheaper to produce than standard titanium

- added the researchers, emphasizing the importance of this technological innovation.

Scientists have made significant progress in materials science by presenting a new titanium alloy for 3D printing, which is stronger and more accessible due to the use of more efficient materials. This development could have great significance for various industries and medicine, opening new perspectives for the use of titanium in the production of space technology and medical implants.

Read also